Introduction

This model is a high speed model,suitable for card board,A/B/C/E/F flute corrugated board,it is applied into folding and gluing of Lock-bottom box,Double sides box(two sides glue),Straight line box(one side glue),Flat mouth box.

This machine has correction device and bottom lock device.Can make electrical adjusting .Has UV destroying device and dust removing device for better gluing effect.

Technical parameters

|

Model No |

GSF-850LB |

GSF-950LB |

GSF-1100LB |

||

|

Max.speed( m/min) |

400 |

400 |

400 |

||

|

Power(kw) |

17 |

17 |

19 |

||

|

Dimension(cm) |

1600*200*150 |

1600*210*150 |

1600*230*150 |

||

|

Weight(kg) |

7000 |

8000 |

9000 |

||

|

Paper Material |

Card paper 200-800g/m² |

||||

|

Corrugated paper A B C E F-Flute (Single Wall & Double Wall) |

|||||

|

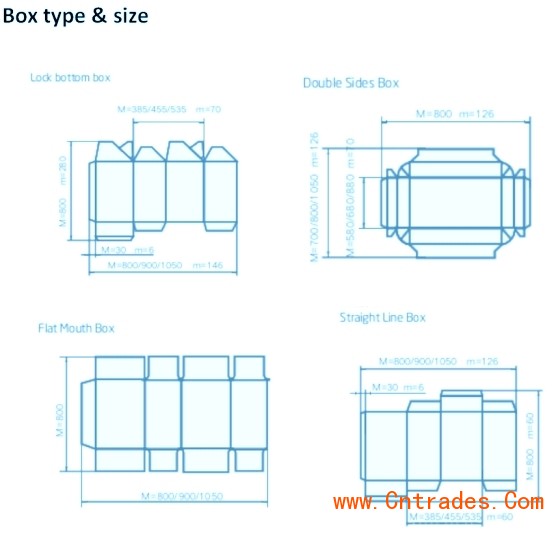

Box type &size |

Box size (mm) |

||||

|

Box type |

Lock-bottom box |

Max. |

800*800 |

900*800 |

1050*800 |

|

Min. |

146*280 |

||||

|

Double sides box |

Max. |

700*800 |

800*800 |

1050*800 |

|

|

Min. |

126*126 |

||||

|

Straight line box |

Max. |

800*800 |

900*800 |

1050*800 |

|

|

Min. |

126*60 |

||||

|

Flat mouth box |

Max. |

800*800 |

900*800 |

1050*800 |

|

|

Min. |

|||||

Machine configuration:

1.Bearing: NSK (Japan)![]()

2.Frequency Converter: Schneider (Germany)![]()

3.PLC system: Schneider (Germany)![]()

4.Multi-wedge belt and pulley: HUTCHINSON (France)![]()

5.Conveyor belt: Rapplon(Swiss)![]()

6.Flat belt:NITTA(Japan)![]()

7.Main motor: TECO (Taiwan)![]()

8.Pressing motor: CPG (Taiwan)![]()

9.Touch screen: WEINVIEN(Taiwan)![]()

Optional:

10.Plasma surface treatment system:Domestic famous brand

11.Servo motor: YASKWA (Japan)![]() (for 4/6 corners box)

(for 4/6 corners box)

12.Spraying adhesive(glue) system :(for 4/6 corners box)

13.Automatic paper stacker

14.Notes: Other parts can be configured as your requirements

Machine Parts

Feeder Section

With independent transmission,low noise,with front adjustable wheels,max working capacity can be achieved.

Feeding knives and left and right registers fixing bar are controlled up and down by pneumatic system easily.

Feeding knifes are equipped with pneumatic mechanism Feeder Section

for smoother feeding.

Paper Alignment System

Automatic alignment system to correct the paper feeding,

avoiding the paper going to sides.UV destroying device

and dust remove device for better gluing effect.

Pre-folding Section

Ensure the completion of 1st folding of 180 and 3rd folding

of 135°,facilitate paper box opening when it is filled .

Bottom Lock Section

Equipped with hook combination adjusting mechanism,

ideal design,easy to operate,configuring high spring hook

and hook box module ensure smooth accurate action

Adjustable hook device ,modular design is convenient to

set and transfer for attachment.

Gluing system

Upper gluing adopts electronic spraying glue system,

equipped with three guns.

Two lower gluing tank,big-volume design,when the

machine is running at high speed,the glue will not go out or leaking .

Folding Section

Equipped with speed variator for belts,ensure the folded boxes parallel and in good order

Fast,convenient adjustment and operation can fold boxes perfectly

The middle up and down transmission module can fold boxes synchronously or alternately

Trombone section

Upper and lower drive mechanism for length adjustment

Equipped with automatic belt tension-adjusting system

Automatic tracking count,kicking,and automatic detect,stop

and alarm when paper inserted.

According to the model and box type ,you can select

pneumatic lock bottom box neat device or

automatic accumulating box device.

Continuous and automatic accumulating box device that ensures

a neat and smooth transmission

Conveyor Section

Drived by independent motor drive, pressure adjusting

with pneumatic device.

According to different length of box,upper belt can

Move back or forward.

This section is 5.6 meters long,to extend paste time,

improve the quality of paste.

Characters

1.High speed

Up to 400m/min

2.Multiple functions

Suitable for card paper & corrugated paper

Applicable to Lock Bottom box, Two Sides Gluing box, Straight Line box, Flat box

3.High performance and excellent quality

Main parts adopt imported parts or domestic famous brands

4.Simple and convenient operation

Touch screen,button and remote controller can operate equipment

independently.

A hexagonal wrench can adjust most of the parts

5.Intelligent and modular design

Feeding section,Adjusting system, Lock bottom section, Gluing system ,

Folding section, Trombone section, Conveyor section.Each section can be

added or subtracted easily

Packaging & Delivery

Packaging Details:

Export wooden box or steel pallet

Delivery Detail:

Shipped in 30 days after payment